JEC World 2022, Part 1: Highlights in sustainable, digital, industrialized composites

Last updated on 6/3/2022

JEC World 2022 offered numerous new developments in composites materials, processes and applications, according to CW senior editor, Ginger Gardiner, most targeting improved sustainability for wider applications.

Source | CW, Ginger Gardiner.

Designing for automated composites manufacturing of low-volume aerostructures

Last updated on 11/1/2021

The OPTICOMS Clean Sky 2 project is pursuing a design, materials and manufacturing solution for cost-efficient and automated fabrication of a composite wing box for low-rate aircraft production. Led by Israel Aerospace Industries (IAI), the project uses a three-spar design with a “working” skin.

Source | CW, Jeff Sloan.

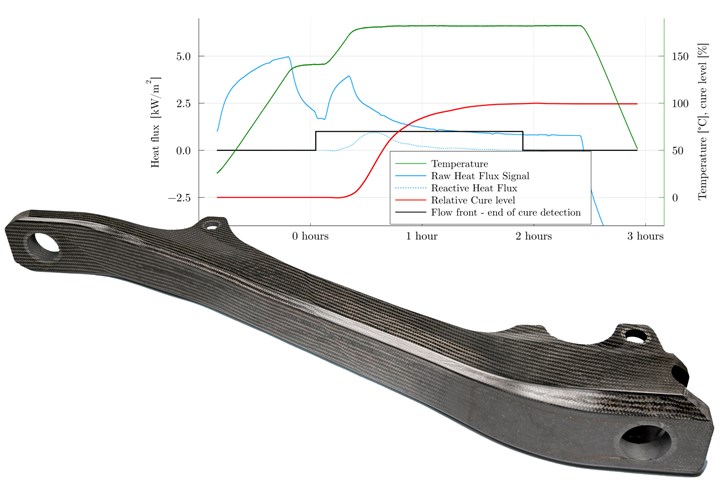

Speeding RTM with heat-flux sensors

Last updated on 6/28/2021

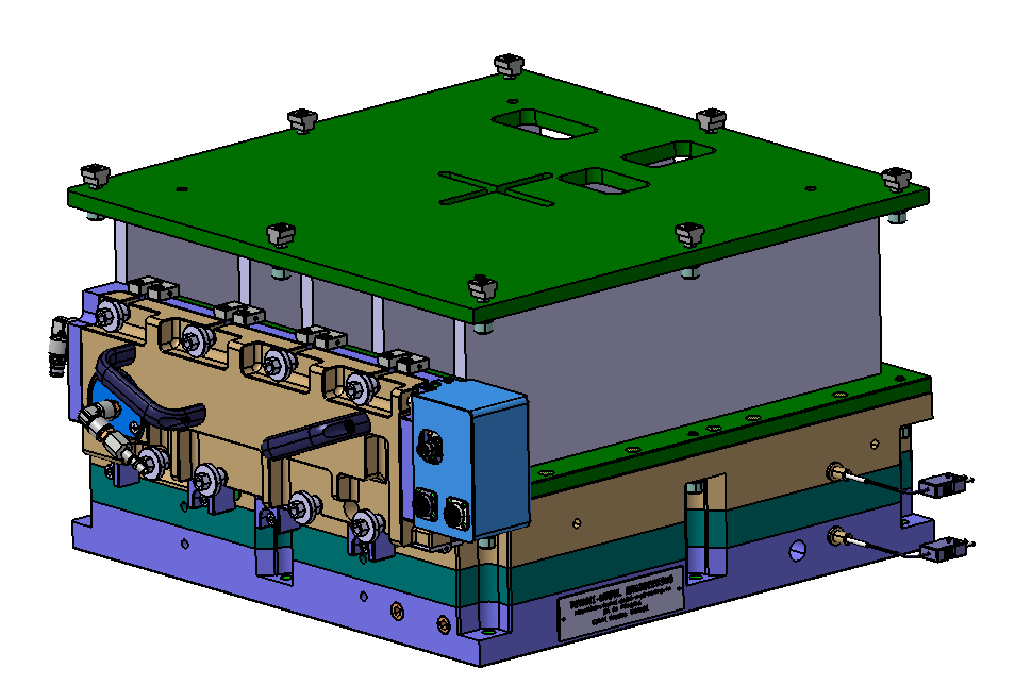

Clean Sky 2 INNOTOOL 4.0 project involves Techni-Modul Engineering as a Coordinator. TME designed and realized an innovative connected RTM tool. “INNOTOOL 4.0 seeks to demonstrate sensor-integrated tooling that will lead the way to smaller tools with less mass for faster production cycles, easier handling and reduced energy consumption, as well as increased automation for lower cost and composites 4.0-intelligent process control.”.

Source | CW, Ginger Gardiner.

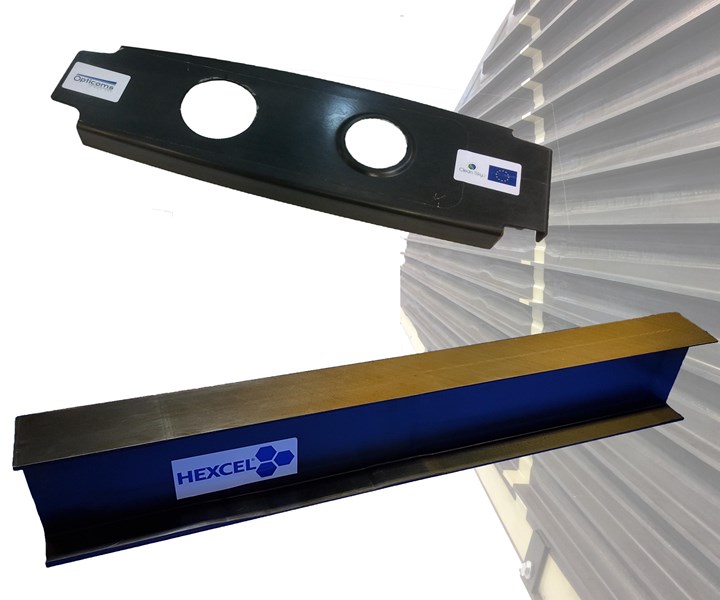

Compression RTM for production of future aerostructures

Last updated on 3/31/2020

Techni-Modul Engineering and Hexcel partnered to demonstrate production of CFRP ribs and stringers using automated preforming and a fast-injection form of resin transfer molding (RTM). The goal is affordable, OOA primary structures like this infused wingskin made by Premium Aerotec using Solvay materials.

Source | CW, Ginger Gardiner.